Our products

ROCKBAR® rebar

ROCKBAR® basaltfiber rebar

Basaltfiber rebar is a Sand-Coated Structural Reinforcing Rod made of a combination of high quality basalt roving (up to 85% by weight) and resin matrix. Sand-coated surface provides high concrete bonding while basalt filaments impart tensile strength.

Length - up to 14 meters

Diameter - 2-36 mm

ROCKBAR® fiberglass rebar

Fiberglass rebar is a Sand-Coated Structural Reinforcing Rod made of a combination of high quality fiberglass roving supplied by US Company (up to 85% by weight) and resin matrix. Sand-coated surface provides high concrete bonding while fiberglass filaments impart tensile strength.

Length - up to 14 meters

Diameter - 2-36 mm

Customized bent products

Customized rebar is a Sand-Coated Structural Reinforcing Rod made from a combination of high quality basalt/fiberglass roving (up to 85% by weight) and resin matrix. Sand-coated surface provides high concrete bonding while basalt/fiberglass filaments impart tensile strength. Each product is obtained a custom shape.

Diameter 2 - 36 mm

ROCKMESH® composite mesh

ROCKMESH® composite mesh

Composite Mesh consists of the FRP bars, arranged in the perpendicular pattern to each other and plastic fixings in the bars cross points. The rods have the same high quality and properties as our standard FPR rebars.

Cell size 50x50 mm

Cell size 100x100 mm

Wire diameter 2.2 mm

Insulation anchors

Isolation anchors for ventilated facades

The fagade dowel consists of the following components:

– anchoring element - plastic plug

– expansion element - composite bar

– plate-shaped element - restrainer made of impact and frost

resistant plastic

Anchor length - 100-700 mm

Bar diameter - 6 mm

Length of a plug anchoring section - 45 mm

Plate-shaped element diameter - 80 mm

Thermosave insulation anchors for plaster facades

THERMOSAVE insulation anchor consists of the following components:

– anchor element - plastic plug

– expansion element - composite bar

– plate-shaped element - restrainer made of impact and

frost resistant plastics

Anchor length - 90-300 mm

Bar diameter - 6 mm

Length of a plug anchoring section - 45 mm

Plate-shaped element diameter - 60 mm

Wall ties

Wall ties for brick work

The wall tie for masonry is a FRP bar with two sand anchors.

Wall tie length - 250-650 mm

Bar diameter - 6 mm

Wall ties for in-situ and brick walls

The wall tie for in-situ and brick walls consists of the

following components:

- anchoring element-plastic plug

- FRP bar with uniform sand coating

Wall tie length - 180-650 mm

Bar diameter - 6 mm

Length of a plug anchoring section - 70 mm

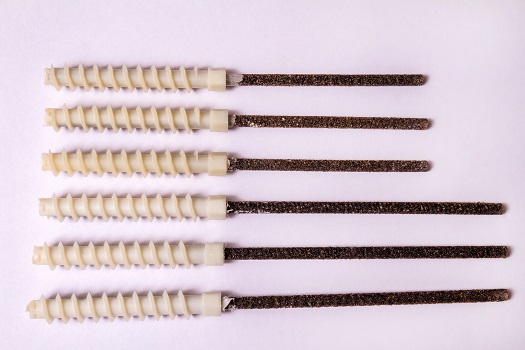

Wall ties for aerated concrete

The wall tie for aerated concrete consists of the following

components:

- anchoring element - molded plug from high

strength plastics

- FRP bar with uniform sand coating

Wall tie length 1- 90-500 mm

Bar diameter - 6 mm

Length of a plug anchoring section - 0 mm

Wall ties for large panel construction

The tie connector for large panel construction comprises the

following elements:

For the use in a bearing panel:

- FRP bar with a uniform sand coating

- Plastic restrainer

- Stainless steel collar

For the use in a non-bearing panel:

- FRP bar with a uniform sand coating

- Plastic restrainer

a) with a restrainer installed at 45°

b) with a restrainer installed at 90°

Tie connector length - 120-500 mm

Diameter - 6 mm

Minimal anchorage length - 60 mm

Wall ties for low-rise construction

A composite rod with a diameter of 4 mm with a continuous sand coating.

Length - 150-700 mm

Diameter - 4 mm

Combined wall ties

Consists of the following elements:

- L-shaped tip (coupling) made of stainless steel;

- basalt-plastic rod with a continuous sandy coating.

To fix the heat-insulating layer in the wall structure with a ventilated gap, a plastic retainer is used (supplied separately).

Length - 165-365 mm

Diameter - 5 or 7 mm

Length of the junction of the coupling with a wall tie - 20 mm

Fasteners

Manufactured from shock-resistant and frost-resistant polypropylene.